Release liners are thin, flexible materials used to protect adhesive surfaces until they are ready for use. They also prevent adhesives from sticking to themselves during storage and transit. Liners are commonly used with pressure sensitive adhesives to make products including labels, tapes, graphic films, medical applications, and much more. Some liners also allow for easy sheeting and die cutting.

Release liners are thin, flexible materials used to protect adhesive surfaces until they are ready for use. They also prevent adhesives from sticking to themselves during storage and transit. Liners are commonly used with pressure sensitive adhesives to make products including labels, tapes, graphic films, medical applications, and much more. Some liners also allow for easy sheeting and die cutting.

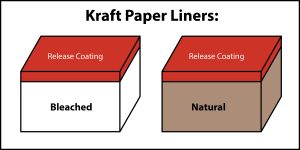

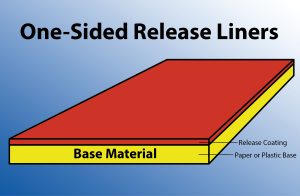

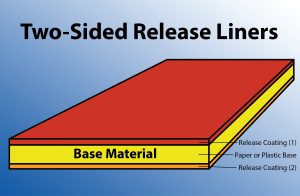

Release liners are typically made from paper or plastic films such as polyester (PET). They can be release-coated on one or both sides, depending on where and how they are used. Silicone is the most common release agent used on liners, but other versions are available with different release coatings.

D&K Group now offers stock and custom release liner products. Highly sophisticated liners are also available for electronic applications that require no solvents or other residual components. Contact your D&K sales representative for current liner availability and pricing.

One-Sided Release Liners:

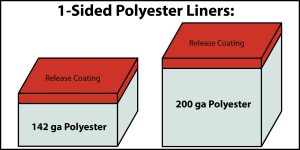

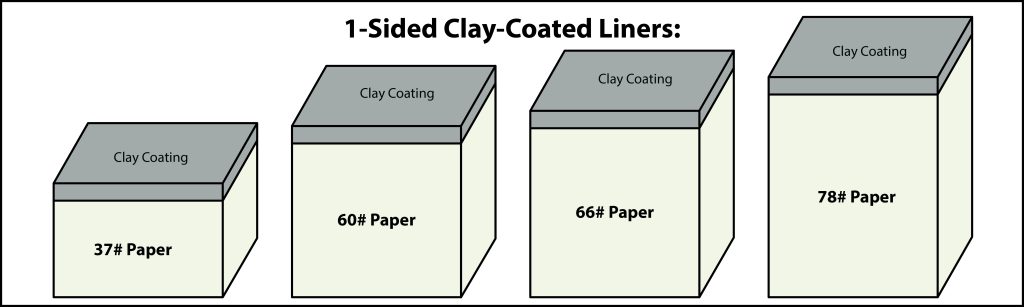

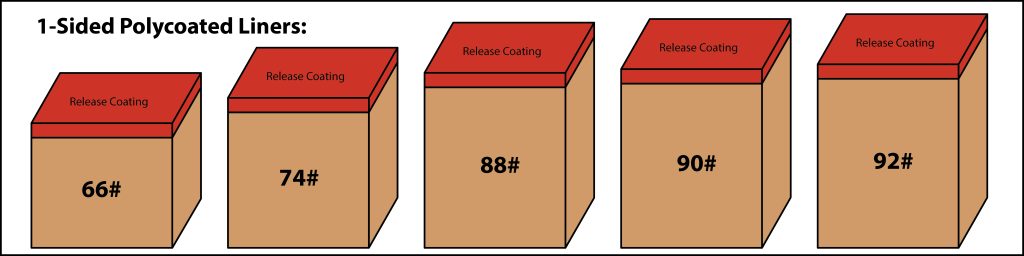

Liners with a single release coating are suitable for pressure sensitive laminating films. One-sided liners are also ideal for other products that feature an exposed adhesive or similar surface requiring removable protection. Thicker liners offer increased strength and rigidity to assist with cutting and application.

- One-Sided Polyester Liners: 142 ga and 200 ga (different release characteristics available)

- One-Sided Clay-Coated Liners: 37#, 60#, 65#, and 78# weights available

- One-Sided Polycoated Paper Liners: 60#, 74#, 88#, 90#, and 92# weights available

Two-Sided Liners:

Two-sided liners include special release coatings on both sides. These coatings usually have different release strengths so that products unwind properly when unrolled. They are typically used with mounting adhesives or tapes that contain adhesive on two sides. Two-sided liners are also ideal for general protection and anti-stick purposes. Thicker liners offer additional strength and rigidity.