Description

System 2760 Automatic Laminator Features

- Fully automated one sided laminating system.

- Can handle sheets from 8.5″x11″ up to 30″ at speeds up to 60 fpm.

- Curl management system places laminating film on the paper in a relaxed manner for a flat finished product.

- Digital touch pads controls allow for easy operation and precision adjustments.

- Swing-out supply mandrel for quick laminating film changeovers.

- Optional quick changeover embossing roller for textured film finishes.

- Easy sheet feed loader allows access from the top, side or back of the feeder, making job changeovers a snap.

- Optional pressure sensitive release liner rewind for high speed processing of pressure sensitive (cold / PSA) films.

System 2760 Automatic Laminator Specifications

- Lamination System Dimensions: 5′ W x 14′ L x 5′ H (152.4 cm x 442 cm x 152.4 cm)

- Electrical: 230 Volt 30 amp single phase

- Air: 6 cfm

- Laminator Warmup Time: 20 minutes

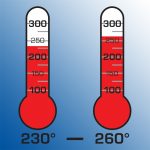

- Temp. Range: 180°F – 300°F (70°C – 140°C)

- Lamination Speed: Up to 60 fpm (18 meters per minute)

- Min Cut Sheet Size: 8.5″ x 11″ (21.6 cm x 27.9 cm)

- Max Cut Sheet Size: 26″ x 30″ (66 cm x 76.2 cm)

- Min Sheet Thickness: 80 lb. Text

- Max Sheet Thickness: 18 pt. Board

Available Options

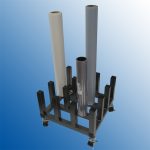

- Embossed roller (for linen and similar textures)

- Release liner takeup to laminate using pressure sensitive films

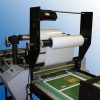

System 2760 Sheet Feeder

- The state of the art automatic sheet feeder and belt table aligns sheets for accurate registration and processing. The System 2760 is equipped to handle a wide range of stocks from letter size up to 26″ x 30.” An extended feeder option is also available to process sheets up to 40″ long.

System 2760 Laminator

- The System 2760 laminator provides accurate heat and nip pressure controls, perfect for even the toughest offset and digital prints. A patented curl management system places the film on the paper in a relaxed manner for a flat, finished product. The main laminator roller can also be easily switched out with an embossed roller option for textured finishes including linen. Laminating films and adhesives are easily loaded onto a swinging supply mandrel that is equipped with sideways adjustments and centering marks. A pressure sensitive release liner rewind option also offers the ability to run pressure sensitive (cold) adhesive products at top speed.

System 2760 Cutter

- The automatic cutter offers complete sheet separation without bursting. Physically cutting sheets with a blade instead of bursting offers the ability to process films thicker than 1.3 mil. The cutter is also compatible with polyester films and will not result in frayed edges that make stacking and registering sheets difficult.

Click here to download System 2760 sales literature

Made in the USA

Made in the USA